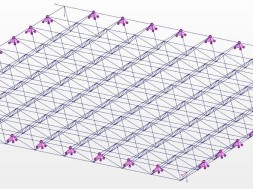

FEM BASED ANALYSIS

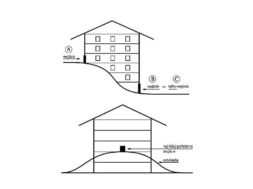

Of wing wall to culvert connection. As part of transportation systems, culverts are subjected to complex load conditions such as earth pressure and traffic live load. The objective of this paper is to study factors that lead to crack formation in the culvert-wing wall connection immediately after construction.

Culverts are a type of hydraulic structures, that are often used in highway infrastructure. A culvert is distinguished from a bridge in that is fully embedded into the soil (1). Culverts are often advantageous over the short span bridges due to economic feasibility and environmental sustainability, especially in case of low road embankment. They require less construction time and maintenance costs. Nevertheless, the failure of the culvert components may interrupt highway service. Culverts can be classified as arch, box, circular, or masonry (2). Typical materials for culverts are reinforced concrete, corrugated metal, solid-wall and strengthened plastic (3). Wood, cast-iron, vitrified clay pipe, and stone box culverts were used in the past (4). This article focuses on crack formation in concrete cast-in-place (CIP) culverts. They are preferable to others due to load carrying capacity (wide waterways, deep embankments), high resistance to environmental hazards (such as corrosion or temperature changes during freeze-thaw periods) and low maintenance cost (5). In comparison with precast sections, CIP culverts can be specially designed to meet the specific site requirements.